ASME B16.5: Pipe Flanges and Flanged Fittings

ASME B16.5: Pipe Flanges and Flanged Fittings

What is the purpose of ASME B16.5 Pipe Flanges and Flanged Fittings?

ASME B16.5 specifies

- Dimensions

- Materials

- Pressure-temperature ratings

- Tolerances

- Marking

- Testing for pipe flanges and flanged fittings.

Where ASME B16.5 applicable (Materials And Units)?

- It applies to flanges with nominal pipe sizes (NPS) ranging from ½ inch to 24 inches

- Fittings made from materials such as steel, nickel alloys, and other ferrous materials.

- ASME B16.5 is limited to

- Flanges and flanged fittings made from cast or forged materials

- Blind flanges and certain reducing flanges made from cast, forged, or plate materials

Flanges and Flanged fittings units

- Both metric and U.S. Customary units

- Flanges with rating class designations 150, 300, 400, 600, 900, and 1500 in sizes NPS 1∕2 through NPS 24

- Flanges with rating class designation 2500 in sizes NPS 1∕2 through NPS 12

- Flanged fittings with rating class designation 150 and 300 in sizes NPS 1∕2 through NPS 24

- U.S. Customary units

- Flanged fittings with rating class designation 400, 600, 900, and 1500 in sizes NPS 1∕2 through NPS 24

- Flanged fittings with rating class designation 2500 in sizes 1 ∕ 2 through NPS 1 2.

US Customary units include units for measuring length, weight, capacity, and temperature. For instance Length: Measured in inches, feet, yards, and miles; Weight: Measured in ounces, pounds, and tons;

- The selection of materials suitable for particular fluid services are not within the scope of this Standard.

Pressure-temperature ratings

Pressure–temperature ratings are maximum allowable working guage pressures in bar units at the temperatures in degrees Celsius. Besides pressure in psig and Temperature in degree F heat also provided

- Ratings of Flanged Joints

- If two flanges in a joint have different pressure-temperature ratings, the joint’s rating will be the lower of the two at any given temperature.

- A flanged joint is composed of separate and independent components: the flanges, gasket, and bolting, all these elements to

attain a joint that has acceptable leak tightness.

Impact of Temperature on Flange

- At High Temperature

- When temperatures cause flanges, bolts, and gaskets to relax, bolt loads decrease.

- This can lead to leakage in flanged joints, especially if subjected to thermal gradients.

- At temperatures above 200°C for Class 150 and 400°C for other classes, care is needed to prevent severe external loads and thermal gradients to avoid leakage.

- At Low Temperature

- Some materials, especially certain carbon steels, may lose ductility at low temperatures and become unable to resist shock, stress changes, or high-stress concentration.

- Some regulations may require impact testing even at temperatures above −29°C.

- It is the user’s responsibility to inform the manufacturer of these requirements before making a purchase.

Testing

- Flanged joints and fittings can be tested at 1.5 times the 38°C (100°F) pressure rating, rounded up to the next 1 bar (25 psi).

- Any higher pressure testing is the user’s responsibility, following relevant codes or regulations.

Identification Markings

- Manufacturer’s name

- Material used to be mentioned

- Rating Designation i.e., 150, 300, 400, 600, 900, 1500, or 2500

- Mention designation B16 or B16.5.

- Temperature markings are not required on flanges or flanged fittings

- NPS designation shall be marked on flanges and flanged fittings

- The edge (periphery) of each ring joint flange shall be marked with the letter R

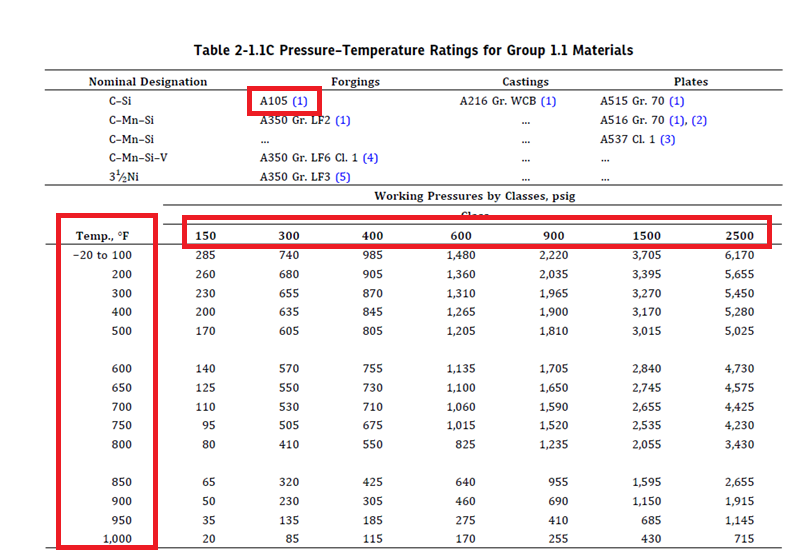

Pressure-Temperature Ratings

Step 1. First Select the Table from below the List of Materials provided in ASME B16.5. Here we consider A105.

Step 2. Refer to the table. 2-1.1 taken from the list and identified the rating as shown below.

Example

- Consider pressure 19.2 and Temperature 48°C. The rating will be 150#.